Your salmon farmer

Innovation

Salmon farming is a science-based industry and research is crucial to finding ways to continually improve. We are involved in many different projects.

Our employees are farmers and innovators who are always exploring the question ‘what if’. We encounter many challenges and opportunities as we deepen our knowledge of sustainable salmon farming and we are always pursuing opportunities to improve fish health, farming technology, nutrition and sustainability.

The fish farms of today do not resemble fish farms of the past and through our commitment to ongoing innovation, research, and pursuing new technologies and partnerships, we are confident that the fish farms of tomorrow will continue to evolve.

Looking to new technologies to improve fish welfare and farming practices

The Salar, our custom-built Hydrolicer

As an organization, we have made the commitment to look to mechanical sea lice removal as our first tools. The Salar uses nothing more ocean water and fluctuating water pressure to first loosen and then remove sea lice and eggs from our fish. The removed lice and eggs are then filtered out of the water used for treatment and stored for disposal on land.

The treatment time per fish is less than 30 seconds and is effective at removing more than 92 per cent (92%) of lice and eggs and is able to treat an entire farms in a matter of days.

The Salar is based out of our operations on the west coast of Vancouver Island, but can be used at any of our farms.

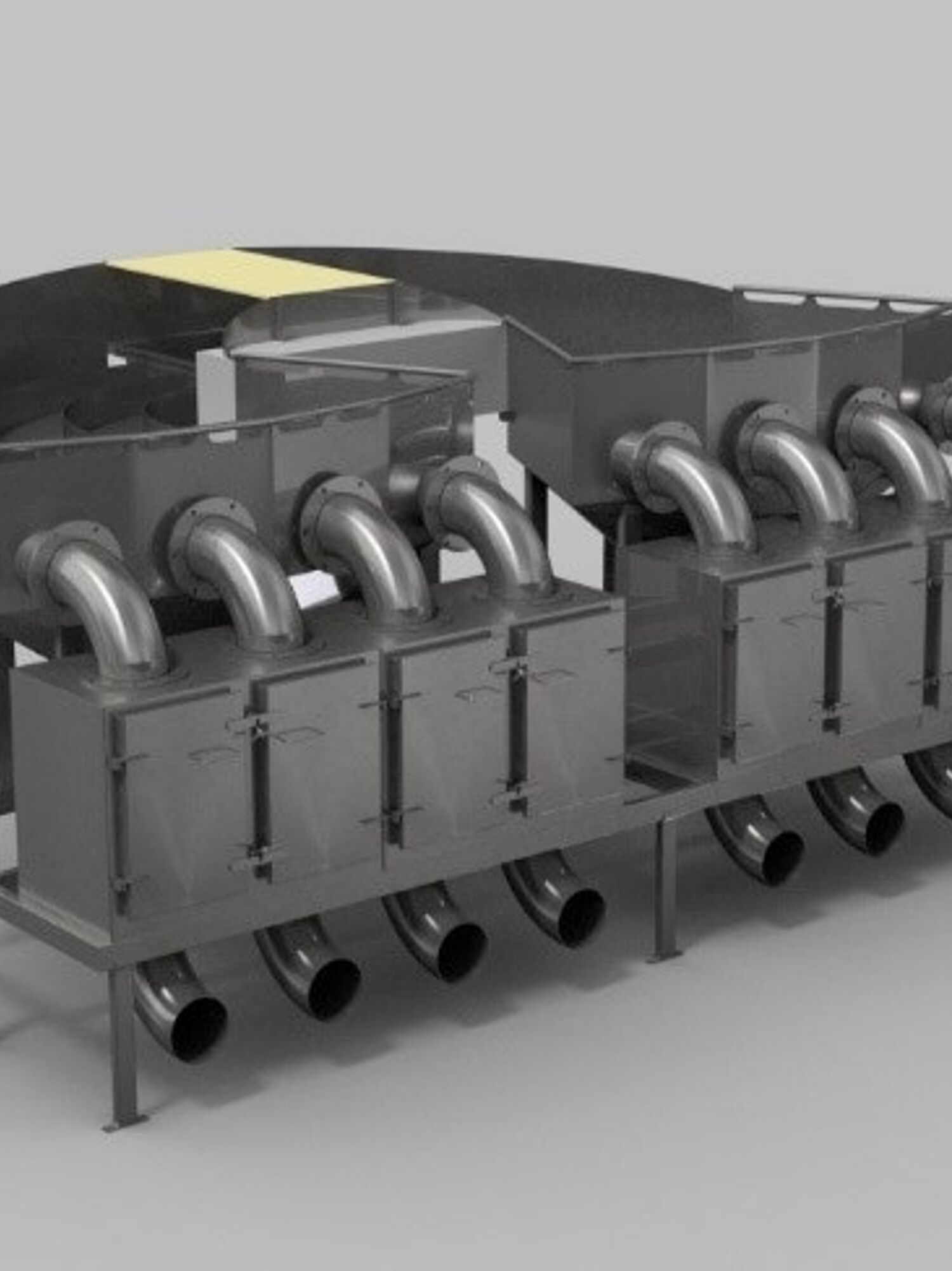

The Sea Farmers Innovations System (SFI System)

Building on the success seen with the use of our Hydrolicer, the Salar, we have invested in new mechanical sea lice removal technology for use at our all saltwater farm sites on the east coast of Vancouver Island

The new system, called a Sea Farm Innovations System (SFI), uses only pressurized, ambient-temperature ocean water to remove sea lice and eggs using directional spray. No chemicals or medications are used for the treatment and the system captures the removed lice and eggs for disposal on land following treatment.

The system is mounted to a vessel and can be easily transported to all of our sites and under ideal circumstances, can treat 200 metric tonnes of fish per hour. The treatment time per fish is less than .02 seconds - which makes it very effective at treating our fish, while reducing stress and handling time.

The system is currently being constructed, and is expected to arrive in Canada in early 2021.

Trialing of Closed Containment (CCS) technology

The trial, which is being carried out at our Millar Channel farm site, runs through until 2025 and based on trials of the system which have been held in Norway, we are hopeful the system will perform well.

The new system is different from our traditional farms as it uses a patented material to form a fully enclosed lining, or bag which effectively eliminated interactions with wild populations and allows for greater control of the water conditions inside the system for our farmed salmon - creating benefits for both populations. The system works by pumping water into the system through four screened sea water intakes, and exits the bag through 12 deep-level screened ports.

The system also allows for greater precision in farming by providing increased oversight of the environment inside the system by controlling water temperature, dissolved oxygen and preventing sea lice and algae from entering the system. Naturally occurring algae, some species of which can be harmful to fish, and sea lice are usually found in the top layers of the water column. The new system allows us to set the sea water intakes below this depth, which will intentionally limit the introduction of these two organisms into the farm system.

During the trial of the system in Norway, our colleagues saw consistently better growth, overall improved performance and almost no occurrence of sea lice within the CCS.

We are continuing to test this technology under Canadian conditions, which are quite different than those seen in Norway.

iFarm - the next possible big development

By using artificial intelligence and machine learning, Cermaq will be able to identify each fish in a net pen, allowing for targeted health interventions if required and individualized health records for each individual fish.

The iFarm five-year project is the first of its kind and will allow for an individualized fish approach to salmon farming.

The trial of this technology is now underway in Norway, with first batch of fish being transferred in the fall of 2020.

In December 2019, Cermaq Norway was awarded four development licenses for iFarm, and preparation work started in January. Since then, thanks to the efforts and support of many people across Cermaq, BioSort – the developer of the technology, and ScaleAQ, who has supported the delivery of the system, the various components of iFarm are taking shape and we have been able to successfully install the system.

The iFarm project trial will run until 2025, and Cermaq recognizes that we are in the very early stages of the project and that it is a very complex system which will require sophisticated interaction between farming equipment, machine vision and fish behavior in full scale. Here, advanced underwater technology will be developed, and it will work in close interaction with the fish. The knowledge and experience gained from this first stocking of fish will be used to optimize the design for the second stocking, which is planned in 2021.